Industry Institute Collaboration

Industry Institute Partnership Cell has been established at IENT for the purpose of coordinating between industries and IENT. The cell promotes and strengthens the interaction between industries and IENT and acts as liaison office, which makes the process of upgrading research process to cater the needs of industries.

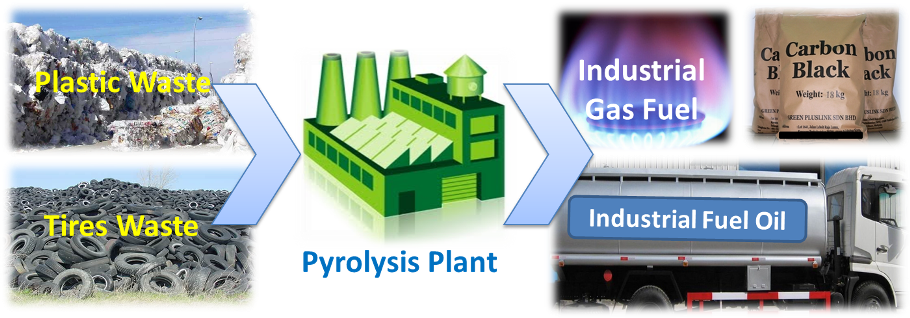

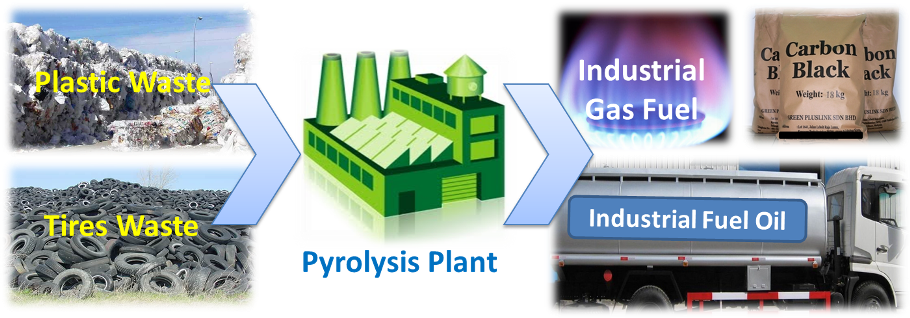

Technology Transfer for Tire Pyrolysis Plant

Pyrolysis plant is an Unit that converts waste plastic & tires into Pyrolysis Oil, Carbon Black & Hydrocarbon Gas.

End products are used as industrial fuels for producing heat, steam or electricity. Pyrolysis plant is also known as: pyrolysis unit, plastic to fuel industry, tire to fuel industry, plastic and tire recycling unit etc.

Pyrolysis plant falls under following categories of industrial projects:

- Waste to energy project

- Waste plastic and tire pollution control equipment

- Renewable energy project

- Petrochemical

We establish large scale pyrolysis plants on Institute Industry Collaboration(IIC) basis . The total turnkey supply includes of machinery designing & simulation, equipment manufacturing, supply, installation, commissioning, technology transfer and operational training.

Advantages of pyrolysis plants manufactured & supplied by TyrePyros Systems:

- Purest quality of pyrolysis oil as finished product

- Use of green technology to achieve Environment friendly processes

- Both plastic & tire can be used as raw material

- Continuous type pyrolysis process

- Breakthrough technologies used to improve safety, profitability & ease of operation

- More than 90% of machinery parts are non-moving: this reduces the recurring maintenance.

- Proven machinery and technology since 2005

- Industry is energy self-sufficient

- No external fuel required for heating

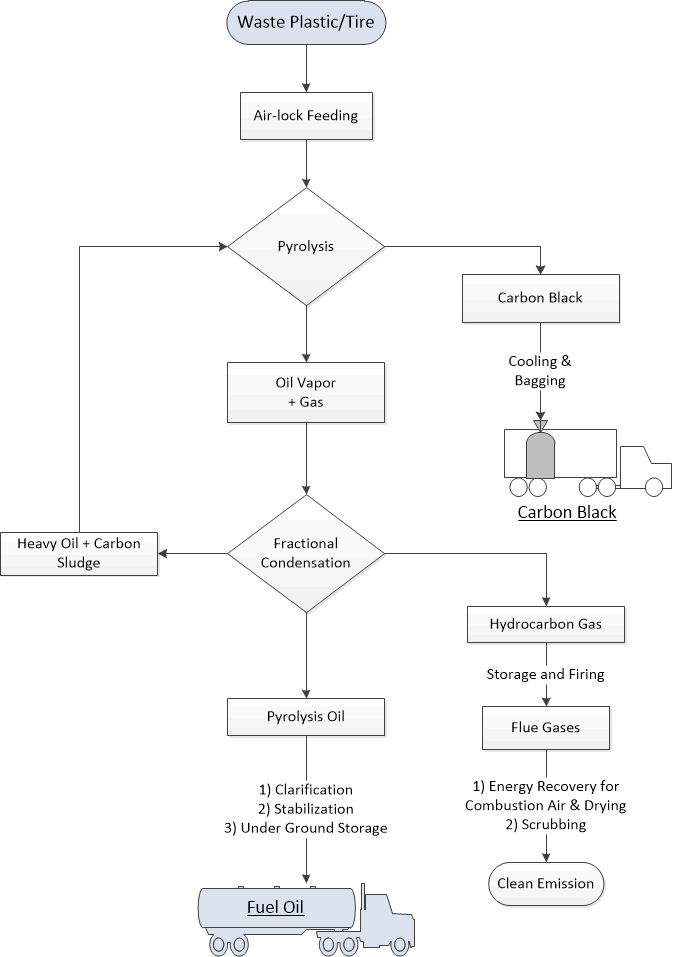

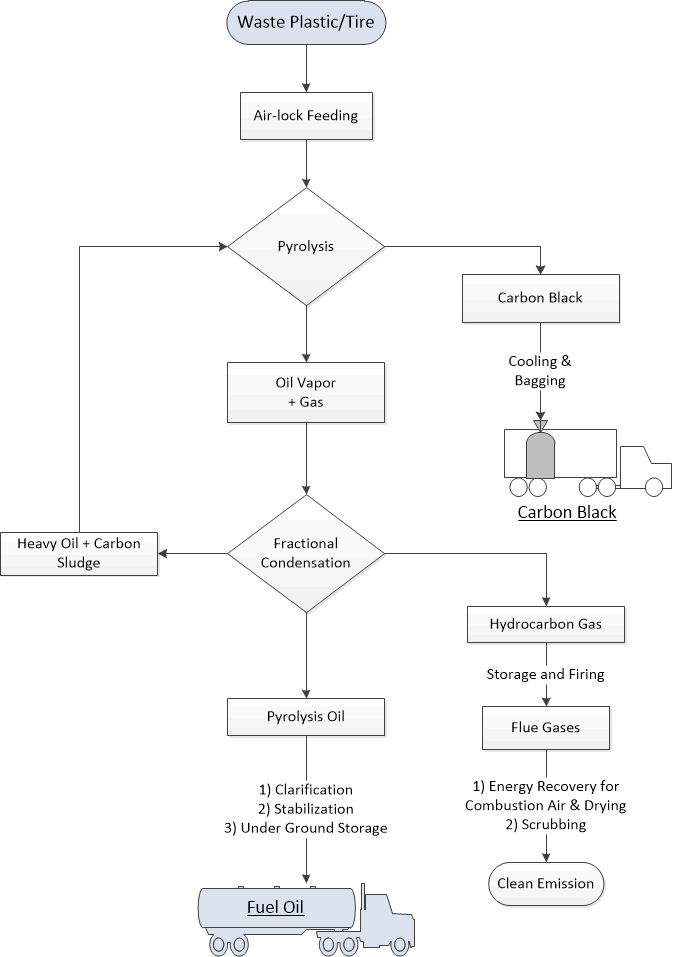

Following diagram shows the typical process flow.

TPO Project Proposal

Limonine Project Proposal

Pyrogas Enrichment Project Proposal

Contact Us